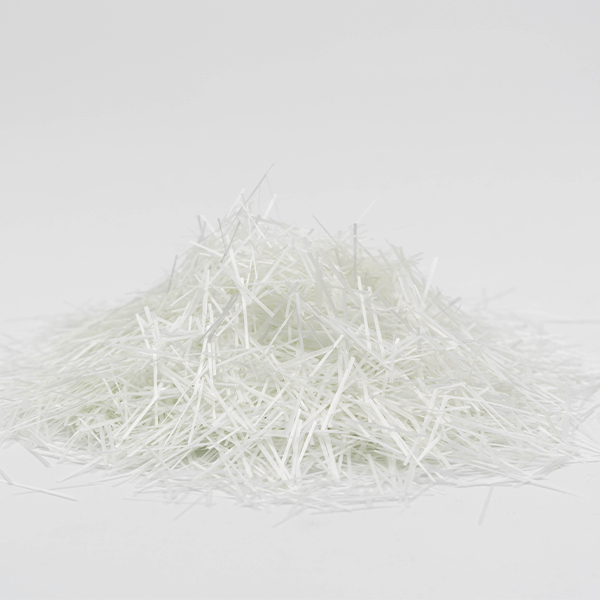

AR Chopped Strands

PERFORMANCE ATTRIBUTES

TO PREVENT CRACK OF GRC COMPONENTS

GOOD INTEGRITY AND NO STATIC ELECTRICITY

GOOD FILAMENT FLEXIBLE AND MAGNIFICENT STRANDS DISTRIBUTION CEMENT

BETTER STRENGTH AND LONGER SERVICE LIFE

|

AR Fiberglass Chopped Strands ZrO2>16.5% |

|||

|

Yarn Density per Strand(tex) |

Content of Fuel(%) |

Moisture Content(%) |

Length(mm) |

|

98±10 |

1.6±0.2 |

≤0.2 |

6、12、18、24 |

|

58±10 |

1.6±0.2 |

≤0.2 |

6、12、18、24 |

Please contact us and tell us the technical parameters of the product you want, and we will find the right product for you.

USAGE INSTRUCTION:

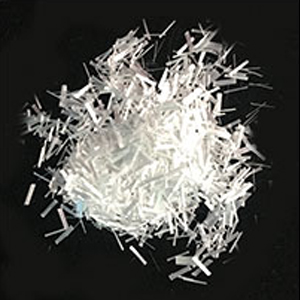

Pre-mixed Fiberglass Chopped Strand

Properties : It has excellent properties with alkali resistance, stiffness, bundle – state, ageing – proof, Mixed 20 minutes in cement at 50rpm, it can still keep good bundle state, it won’t dispersed to filament.

Purpose : It is a high integrity AR Glass Fiber Chopped Strands designed for use in the reinforcement of concrete, renders and mortars. It may be added to conventional mixes either on site or by prepending with other dry mix components. The low – tex strands permits efficient reinforcement at low dosages. They are particularly suited to the modification of standard concrete mixes for floor screeds and slabs,and for the preparation of prebagged mixes of special mortars and renders.

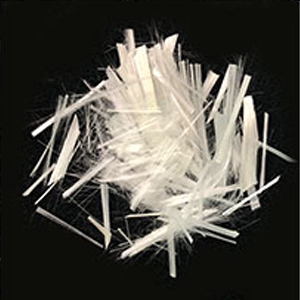

Water-dispersed Fiberglass Chopped Strands

Properties : AR Glassfiber Applied with water – dispersed size, the strands will disperse well to filaments in water in 10 seconds, and also disperse fast, usage amount less, enlarge strength.

Purpose : It is typically used at a low level of addition to prevent cracking and improve the performance of ready mix concrete, floor screeds, renders or the special mortar mixes.it can be used for surface crack – proof of GRC products.

HIGH DISPERSION AR FIBERGLASS

AR fiberglass 6mm

AR fiberglass 12mm

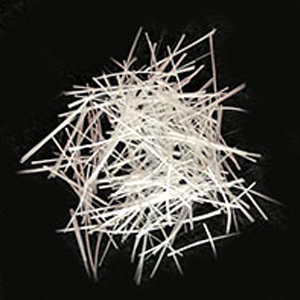

AR846 fiberglass 18mm

HIGH INTEGRITY AR FIBERGLASS

AR fiberglass 12mm

AR fiberglass 18mm

AR fiberglass 36mm

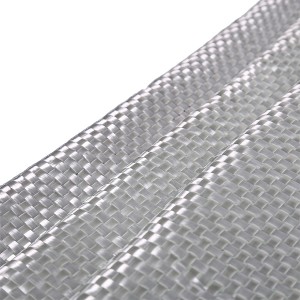

APPLICATION

For the production of standard GRC components, such as sewer pipes or instrument boxes, or various construction facilities such as lightweight partition panels.

We can provide samples for free according to the specifications you want. Our product materials and craftsmanship are strictly and carefully controlled. Before the goods are sent out, we can realize the online on-site inspection of whether the quality of the product is consistent with the quality of the sample. We even welcome you to visit our factory.

Yes, we always use high-quality export packaging. We also use specialized hazmat packaging for dangerous goods and verified refrigerated shippers for temperature-sensitive items. Specialty packaging and non-standard packaging requests may incur additional charges.

We can provide most of the documents including Certificate of Analysis/Certificate of Conformity etc.; as well as Insurance; Country of Origin and other required export documents.

As market factors are constantly changing, we will adjust accordingly. At the same time, we will give corresponding preferential prices according to your order quantity. You can contact us with your doubts and requests, and we will reply to you within 24 hours.

What we do is customized products, we can do it according to the specifications you want. Even for fiberglass products not shown in the list, you can consult us, and we can solve them for you.

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

TECHNICAL SUPPORT

GRECHO also offers Technical Support, which focuses on

trouble shooting and increased productivity for our customers.